IPET INTEGRATED

ELECTRIC POWER TECHNOLOGY

The I-Series products are a fully integrated power system platform developed based on

IPET (Integrated Electric Power Technology) for high-performance multi-rotor UAVs.

The current series includes multiple models

*IPET differs from traditional modular or assembled propulsion systems by directly embedding the ESC inside

the motor. This eliminates the need

for controller wiring harnesses and mechanical enclosures, significantly improving the power system's space

utilization efficiency and power density.

Design Philosophy: All-in-One Integration – Reduced size with compact structure, User-Friendly Operation –

Simplified setup and enhanced reliability

High Safety & Long Service Life – Robust design for sustained performance, energy-efficient & Long Endurance –

Optimized power consumption

for longer flight times, Noise-Reduced & Lightweight Propeller – Improved aerodynamics and reduced weight, ESC

Health Monitoring

Module – Real-time diagnostics for proactive maintenance

IPET INTEGRATED ELECTRIC POWER TECHNOLOGY

The I-Series products are a fully integrated power system platform developed based on IPET (Integrated Electric Power Technology) for high-performance multi-rotor UAVs. The current series includes multiple models

*IPET differs from traditional modular or assembled propulsion systems by directly embedding the ESC inside the motor. This eliminates the need for controller wiring harnesses and mechanical enclosures, significantly improving the power system's space utilization efficiency and power density. Design Philosophy: All-in-One Integration – Reduced size with compact structure, User-Friendly Operation – Simplified setup and enhanced reliability High Safety & Long Service Life – Robust design for sustained performance, Energy-Efficient & Long Endurance – Optimized power consumption for longer flight times, Noise-Reduced & Lightweight Propeller – Improved aerodynamics and reduced weight, ESC Health Monitoring Module – Real-time diagnostics for proactive maintenance

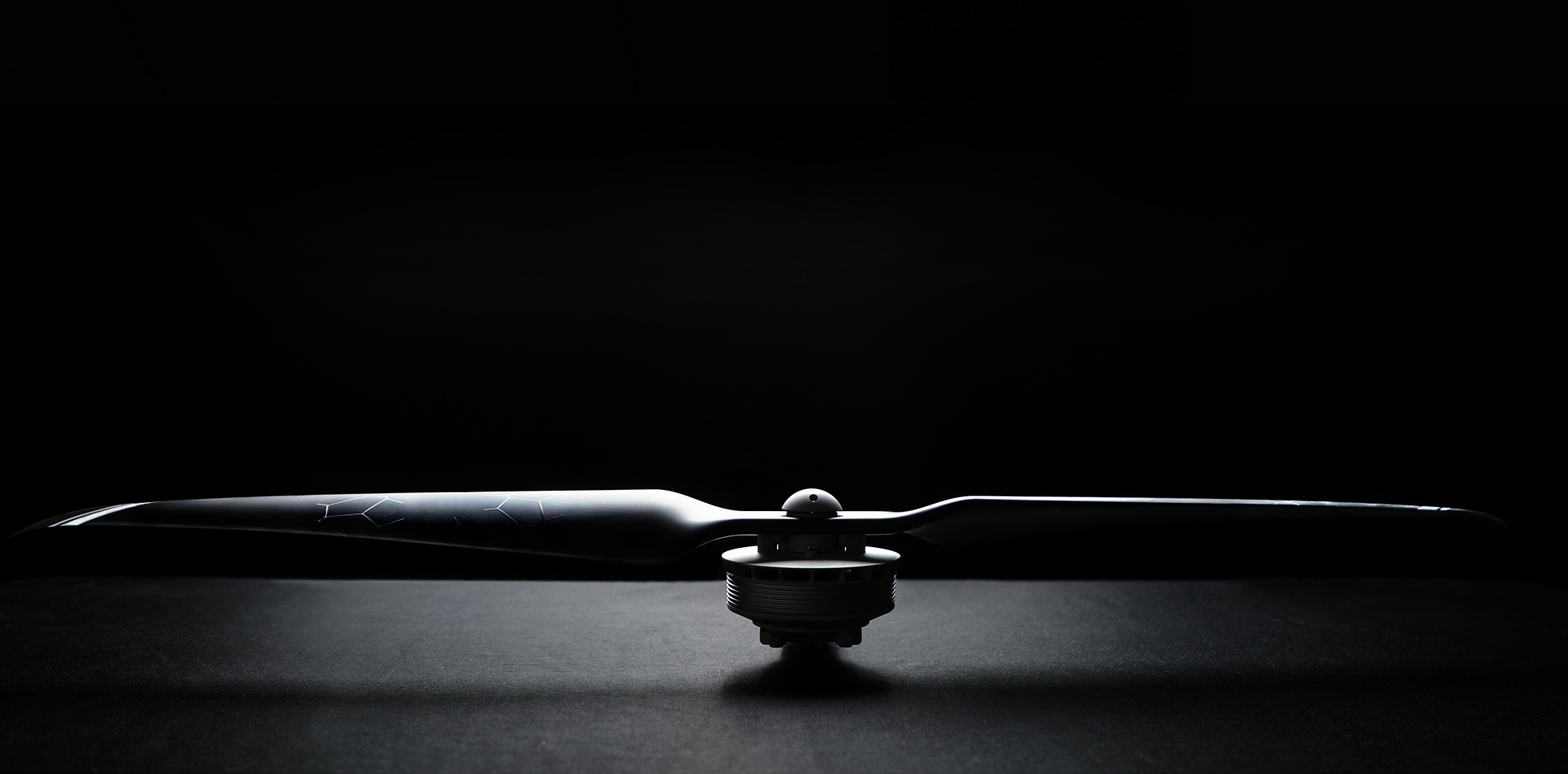

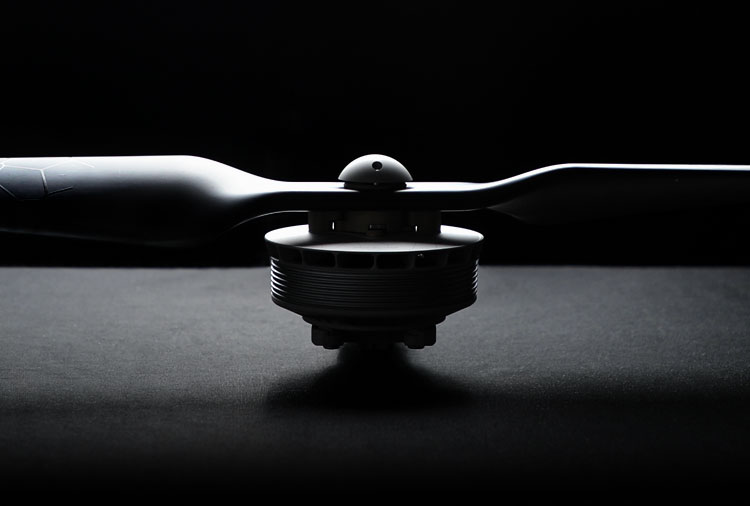

ALL-IN-ONE INTEGRATION

The integrated design features merged

components, eliminating ESC housings and

reducing cable harnesses compared to

separate components. This achieves smaller

size and lighter weight, with the weight savings

compensating for electromagnetic mass to

enhance power density and efficiency.

USER-FRIENDLY OPERATION

Manufacturers resolve complex assembly

challenges-users simply mount the arm

for instant deployment. The propeller

attaches to the motor without screws,

enabling tool-free installation/removal

in seconds.

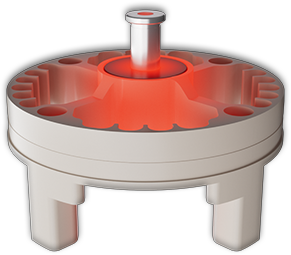

HIGH SAFETY & LONG SERVICE LIFE

Thermo-fit assembly with precision-positioning press technology

significantly improves operational balance. The elevated standards in machining,

assembly processes, and validation testing ensure superior quality.

0+Times

Propeller Hub Installation/Removal Wear Test

10 Times Longer Lifespan Than Class-Competitors

0 Hour

Service Life Standard Operational Duration Of The Power System

0+Hours

Flight Testing

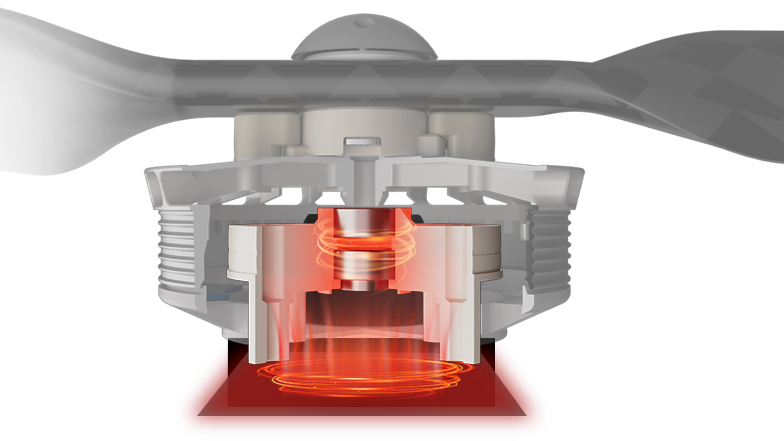

ENERGY-EFFICIENT & LONG ENDURANCE

Electromagnetic field optimization simulation minimizes energy loss. Co-design & co-simulation of motor,

ESC, and propeller for maximum efficiency, boost-ventilation duct design integrates dual functions:

exhaust cooling and oblique thrust boosting to enhance overall system efficiency,

The optimization for specific payloads and takeoff weights significantly extends flight time.

10.35kg

Maximum Takeoff Weight (with 2kg Payload)

120min

Quadcopter Flight Time

*2 times (1-hour longer) flight time than comparable-class UAVs

NOISE-REDUCED & LIGHTWEIGHT PROPELLER

Aerodynamic optimization based on load thrust profiles reduces noise by 15% vs standard propellers.

Parametric blade geometry design with advanced composite materials maintains strength

while

achieving 30~48% weight reduction

*Taking I7 Power System Propeller as Example

50dB/5m

Ambient Noise

67dB/5m

Measured (I30 Propeller)

77dB/5m

Other Conventional Propellers

ESC HEALTH MONITORING MODULE

The ESC integrates a full-lifecycle health monitoring

module with portable edition and professional edition

(to be released). Featuring built-in vibration sensors

and dynamic performance monitoring, it utilizes

diagnostic algorithms to real-time track power system

status & load conditions, identify performance trends

through operational data analytics and predict system

failures. Pre-Flight Status Diagnostics via LED Indicators

*Before each mission, verify power system status through LED patterns to prevent operational risks: Normal Operation: Reverts to default ESC lighting color, Fault Conditions: Coded flashes enable rapid troubleshooting.

PORTABLE EDITION

Without requiring log uploads, the power system

can self-diagnose its condition and alert users via LED

indicators or audible tones to perform preventive maintenance

PROFESSIONAL EDITION

By uploading the logs to the server system, the system would utilize

built-in self-learning algorithms to update power system usage models

for dynamical assess of remaining useful life (RUL),

precision maintenance advice and status of the power system